Teflon™ is a PTFE coating that has excellent non-stick/release characteristics. This means commercial bakeware can be easily cleaned and have excellent nonstick/release properties. We have designed a variety of PTFE systems that are suitable for most applications. The coating’s function and operating conditions will determine the best coating.

Teflon™ is a PTFE coating that has excellent non-stick/release characteristics. This means commercial bakeware can be easily cleaned and have excellent nonstick/release properties. We have designed a variety of PTFE systems that are suitable for most applications. The coating’s function and operating conditions will determine the best coating.

Nonstick and Release: The PTFE coating will provide excellent non-stick/release characteristics and is easy to clean. This coating also prevents both hot and cool products

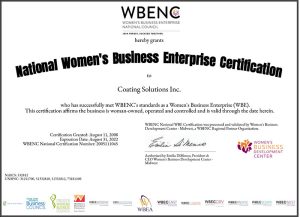

When selecting an industrial fluoropolymer coating provider, there are several options to choose from. Companies that utilize high quality sealants and adhere to industry guidelines will likely offer you a great product in the end. Ultimately though, your final decision on which coating company you select should be based on several deciding factors.

When selecting an industrial fluoropolymer coating provider, there are several options to choose from. Companies that utilize high quality sealants and adhere to industry guidelines will likely offer you a great product in the end. Ultimately though, your final decision on which coating company you select should be based on several deciding factors. Metal abrasion can be expected due to friction, grinding and other wear effects caused by regular machine usage. Coating Solutions provides high-quality Chemours® Teflon™, fluoropolymer industrial coats to industries across America

Metal abrasion can be expected due to friction, grinding and other wear effects caused by regular machine usage. Coating Solutions provides high-quality Chemours® Teflon™, fluoropolymer industrial coats to industries across America Just about every industrial sector uses Teflon™ coated parts in some part of their manufacturing process. Of course, the Teflon brand has been a household name in kitchenware, but there are many other uses for the coating.

Just about every industrial sector uses Teflon™ coated parts in some part of their manufacturing process. Of course, the Teflon brand has been a household name in kitchenware, but there are many other uses for the coating. Teflon™ PTFE, or polytetrafluoroethylene coating, is used in a wide variety of applications. It is used on rollers of various sizes, providing solutions for engineering applications, particularly those applications that require low-friction, non-stick, chemical-resistance or wear resistance. One of the most common uses of PTFE in the printing and paper industry, is in photocopiers, namely fuser, feed, pressure, and guide rollers.

Teflon™ PTFE, or polytetrafluoroethylene coating, is used in a wide variety of applications. It is used on rollers of various sizes, providing solutions for engineering applications, particularly those applications that require low-friction, non-stick, chemical-resistance or wear resistance. One of the most common uses of PTFE in the printing and paper industry, is in photocopiers, namely fuser, feed, pressure, and guide rollers. Screen printing (or the placing of ink on clothing materials) is extremely common and is even opening to individuals that wish to provide small businesses with custom-made clothing articles. Many people would not associate the use of Teflon™ with cloth materials and the screen printing industry, but the use of Teflon™ is quite common! Read on to see how and think about other ways in which the coating experts at Coating Solutions can help your business be more efficient.

Screen printing (or the placing of ink on clothing materials) is extremely common and is even opening to individuals that wish to provide small businesses with custom-made clothing articles. Many people would not associate the use of Teflon™ with cloth materials and the screen printing industry, but the use of Teflon™ is quite common! Read on to see how and think about other ways in which the coating experts at Coating Solutions can help your business be more efficient. Fluoropolymers have been called a “super paint” because of its durable quality and versatility amongst applications. Fluoropolymers are ideal for many industrial applications due to these qualities and more. Coating Solutions in Hugo, Minnesota provides several types for fluoropolymer coatings to extend the life of and reduce wear and tear on your industrial parts.

Fluoropolymers have been called a “super paint” because of its durable quality and versatility amongst applications. Fluoropolymers are ideal for many industrial applications due to these qualities and more. Coating Solutions in Hugo, Minnesota provides several types for fluoropolymer coatings to extend the life of and reduce wear and tear on your industrial parts. There are many direct, and indirect, benefits of using parts that have been coated with some type of fluoropolymer application. Some of the biggest benefits include heat-resistance, extreme weatherability, and having universal chemical compatibility. In the laundry industry, the best, and perhaps most obvious application, is in commercial

There are many direct, and indirect, benefits of using parts that have been coated with some type of fluoropolymer application. Some of the biggest benefits include heat-resistance, extreme weatherability, and having universal chemical compatibility. In the laundry industry, the best, and perhaps most obvious application, is in commercial You might know it as “PTFE”, but it also goes by several other names, including “polytetrafluoroethylene” and its brand name “Teflon.” It is a plastic fluoropolymer that makes a vital contribution to numerous industries that touch our live

You might know it as “PTFE”, but it also goes by several other names, including “polytetrafluoroethylene” and its brand name “Teflon.” It is a plastic fluoropolymer that makes a vital contribution to numerous industries that touch our live When it comes to the application of industrial fluoropolymer coating, there are several options available to you. These are likely companies that would apply high quality sealants and follow certain industry guidelines to ensure that you get a good product in the end. The final choice in what coating company you choose however rests in the culmination of several deciding factors.

When it comes to the application of industrial fluoropolymer coating, there are several options available to you. These are likely companies that would apply high quality sealants and follow certain industry guidelines to ensure that you get a good product in the end. The final choice in what coating company you choose however rests in the culmination of several deciding factors.