Teflon™ Applications In Cabling And Communications

Infrastructures need reliable communications systems to transmit data and information and stay connected. Data transmission efficiency is determined by the quality of cable and wire insulation. Fluoropolymers of high quality allow for thinner and lighter wire and cable insulation walls. This insulation allows for higher data transmissions, including radio signals, telephone reception, internet connections and more.

Infrastructures need reliable communications systems to transmit data and information and stay connected. Data transmission efficiency is determined by the quality of cable and wire insulation. Fluoropolymers of high quality allow for thinner and lighter wire and cable insulation walls. This insulation allows for higher data transmissions, including radio signals, telephone reception, internet connections and more.

Teflon™ resins are used to improve the performance and safety of cables in commercial applications in a lot of different industries.

● Low flammability fuel contribution

● Exceptional dielectric properties

● High-stress crack resistant

● Chemical inertness

● Thermal cycling capability

Fire and smoke characteristics that exceed safety standards: To save time and money during construction, electricians route cables through ceiling and floor cavities. These cables are more resistant to fire and will not spread smoke or flames if there is a fire. According to National Fire Protection Association standards, the Teflon™ fluoropolymer resins meet low fuel load requirements for a limited combustible design. Teflon fluoropolymer is a superior compound insulation because of its strong fire and smoke properties. It can meet insurance and code requirements without adding additives.

PTFE explained: PTFE coatings are non-stick, fluoropolymer, high temp coatings. They have a one-coat system or a two-coat system of a primer and topcoat and have several features that make them go-to coatings. This specific type of coating has the highest operating temperature of all fluoropolymers at 500°F, a low coefficient of friction, as well as good chemical resistance and abrasion resistance. Its non-reactive properties, due to strong carbon–fluorine bonds, makes this coating great for applications that must hold up against volatile and corrosive chemicals.

General benefits of Teflon™: Teflon™ is used for a variety of applications. It’s often used in high-temperature, military, or general-purpose hook-up wire. These cables are durable and can withstand temperatures of -90oC to 260oC. Teflon can be used for applications that need heat resistance, friction resistance or wear resistance. Teflon can be used in automation and robotics as well as air conditioning, navigation systems, power steering, and heated seats for automobiles. Teflon wire and cable are built to last, with strong constructions.

The modern applications of PTFE are virtually limitless. Electrical insulative properties of PTFE make it a great choice for covering wiring and circuit boards in computer, aerospace, and communications assemblies. The low friction of PTFE is ideal for industrial and mechanical parts like bearings and gears. Due to its chemical inertness and extreme thermal resistance, PTFE can be found in many valves, joints and hoses used for transporting and storing alkalis and acids.

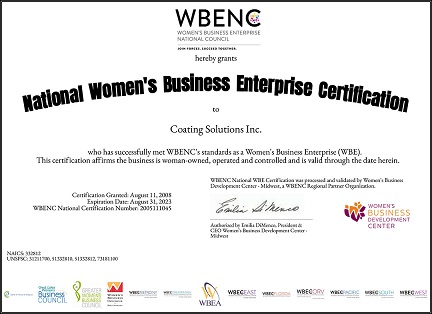

Teflon™ PTFE (polytetrafluoroethylene) coatings meet the exacting military-grade application demands with ease, making them extra-suitable for your specific applications. To discuss how PTFE/Teflon™ can be applied in your specific product(s), contact Coating Solutions at (651) 762-5700 in Hugo, MN, or email sales@coatingsolutions.com to discuss your application needs.